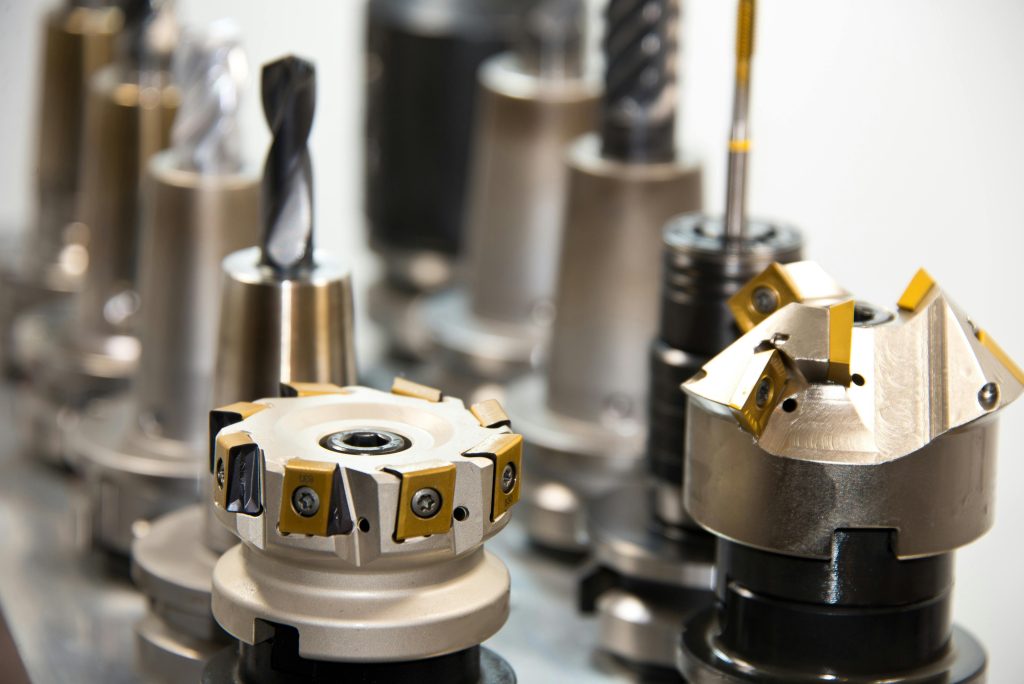

Swiss machining is a critical process in precision manufacturing, often used to create intricate parts with tight tolerances. As a seasoned professional, you already know that the type of cutting oil used in these operations is crucial for both efficiency and Flashpoint Be for Cutting. But what you may not have considered in-depth is the flashpoint of your cutting oil. Understanding what the flashpoint should be for cutting oils used in Swiss machining can have a profound impact on the performance of your operation, safety standards, and overall quality.

In this article, I will walk you through the essential role of flashpoint in Swiss machining, how to choose the right oil for your operation, and why it’s one of the most important factors to consider. By the end of this post, you’ll have a clear understanding of how to optimize your cutting fluid selection for Swiss machining while also ensuring the safety and longevity of your equipment.

Also read this What Technology Makes Your Car Beep When You Lock It?

Why Does Flashpoint Matter for Swiss Machining?

1. Understanding Flashpoint in Cutting Oils

Before diving into specifics, it’s important to first understand what flashpoint is. Flashpoint refers to the lowest temperature at which a liquid will produce enough vapor to form an ignitable mixture with air. For cutting oils used in Swiss machining, this temperature is a critical safety factor.

In high-speed operations like Swiss machining, cutting tools and the workpiece generate significant heat. This heat, if not adequately managed, can lead to the oil vaporizing, which can increase the risk of fire or cause a decrease in lubrication efficiency. Cutting oils with an appropriate flashpoint help to reduce the risk of ignition while also maintaining their lubrication and cooling effectiveness during these demanding operations.

2. The Impact of Flashpoint on Safety

When machining at high RPMs, especially with tight tolerances, the cutting fluid must not only cool but also prevent sparks or other ignition sources from causing catastrophic accidents. Oils with low flashpoints are more volatile and can ignite easily when exposed to heat, leading to dangerous situations.

Swiss machining tools tend to operate in confined, high-heat environments, which makes choosing the right cutting fluid even more important. Ensuring the right flashpoint for your cutting oils ensures a safer environment for both the machinery and your personnel.

What Flashpoint is Ideal for Cutting Oils in Swiss Machining?

So now you’re wondering, what flashpoint should you be looking for when choosing cutting oils for your Swiss machining operations? Let’s break it down.

1. Flashpoint Ranges for Cutting Oils

For Swiss machined parts, the cutting oil should typically have a flashpoint within the range of 300°F to 400°F (approximately 150°C to 200°C). This flashpoint range offers an optimal balance between safety, cooling ability, and lubrication. Here’s why:

- Low Flashpoint Oils (< 300°F / 150°C): These oils are more volatile and can easily catch fire when exposed to high heat. This poses a significant safety risk during high-speed machining operations, making them unsuitable for Swiss machining.

- High Flashpoint Oils (> 400°F / 200°C): While these oils offer better safety by being less prone to combustion, they may lack the cooling efficiency needed for high-speed machining. If the oil’s flashpoint is too high, the cooling performance might degrade under intense friction and heat, potentially damaging the tools or the workpiece.

- Ideal Flashpoint Range (300°F – 400°F): Oils within this range offer the best balance for Swiss machining. They are stable enough to withstand the heat generated during high-speed cuts and have sufficient cooling properties to manage heat buildup, preventing tool wear and ensuring the quality of the finished part.

Factors to Consider When Selecting a Cutting Oil for Swiss Machining

Selecting the right cutting oil for your Swiss machining operations goes beyond just considering the flashpoint. Below are other essential factors to weigh in when making your decision:

1. Viscosity

Viscosity refers to the thickness or flow of the oil. For Swiss machining, the oil’s viscosity should allow it to flow freely while still providing enough lubrication. If the oil is too thick, it may not flow effectively, while if it’s too thin, it may not provide the necessary lubrication or cooling. Always ensure the viscosity is suited to the specific demands of your Swiss machine’s cutting tools and workpieces.

2. Cooling Properties

Cooling is a critical part of Swiss machining, especially when working with precision parts. The cutting oil must dissipate the heat generated during the machining process to prevent overheating, which can result in part distortion, tool wear, or even tool failure. Ensure that the oil you choose offers high cooling capabilities under high-speed operations.

3. Additives

Cutting oils often contain additives that enhance their performance. These can include rust inhibitors, anti-wear additives, and friction-reducing agents. Be sure to choose an oil with the right additives for your operation. These additives can improve tool life, reduce friction, and help maintain the integrity of the workpiece.

4. Environmental Impact

In today’s world, it’s crucial to consider the environmental impact of your operations. Some cutting oils, especially those made from mineral oils, can be harmful to the environment if spilled. In contrast, synthetic or bio-based oils offer more environmentally friendly alternatives. While they may come with a higher upfront cost, they can contribute to a more sustainable operation in the long run.

Types of Cutting Oils for Swiss Machining

There are several types of cutting oils available for Swiss machining, each with its advantages and considerations. Let’s take a look at the four primary categories:

1. Mineral Oils

Mineral oils are the most common and traditional type of cutting fluid. They are derived from crude oil and offer good lubrication and cooling properties. Mineral oils typically have a lower flashpoint, but they may be suitable for operations where extreme temperatures are not a concern.

2. Synthetic Oils

Synthetic oils are engineered for superior performance, especially in high-speed operations. These oils often have a higher flashpoint than mineral oils, making them safer for Swiss machining. They offer excellent cooling and lubrication properties, reducing tool wear and improving part quality. However, they tend to be more expensive than mineral oils.

3. Semi-Synthetic Oils

Semi-synthetic oils combine the best of both mineral and synthetic oils. They offer a good balance between cost and performance, providing good lubrication and cooling properties while maintaining a moderate flashpoint. Semi-synthetics are ideal for many Swiss machining applications.

4. Bio-Based Oils

Bio-based oils are made from renewable resources and are designed to be more environmentally friendly than mineral oils. These oils are biodegradable and tend to have a higher flashpoint, making them a safe and sustainable choice for Swiss machining. However, they can be costlier and may not perform as well under all machining conditions.

Comparison Table of Cutting Oils for Swiss Machining

| Feature | Mineral Oil | Synthetic Oil | Semi-Synthetic Oil | Bio-Based Oil |

| Flashpoint | Lower (250°F – 350°F) | Higher (350°F – 500°F) | Medium (300°F – 450°F) | High (350°F – 450°F) |

| Lubrication Efficiency | Good | Excellent | Good | Moderate to Good |

| Cooling Efficiency | Moderate | Excellent | Good | Moderate |

| Cost | Low | High | Moderate | High |

| Environmental Impact | High | Low | Low | Very Low |